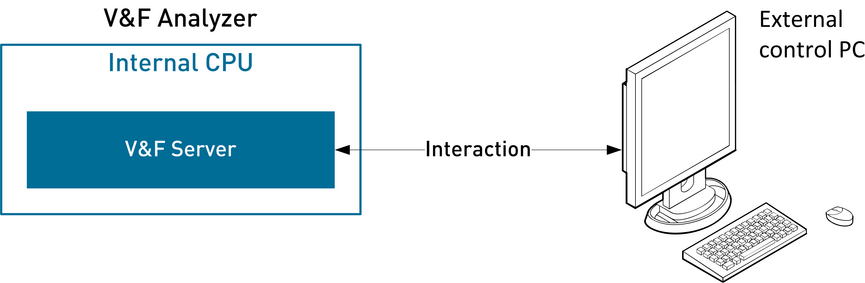

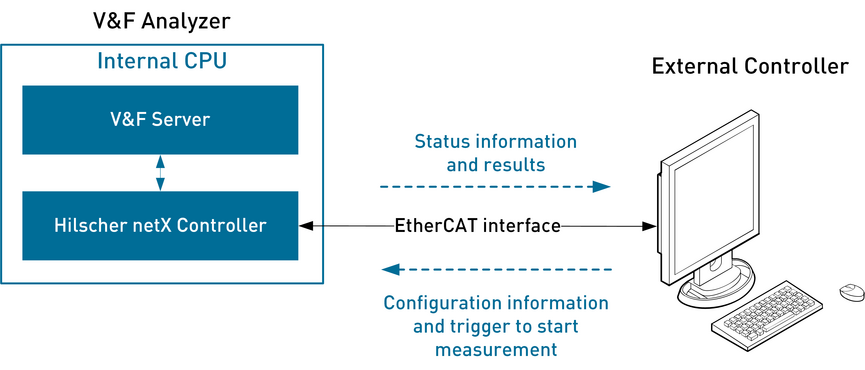

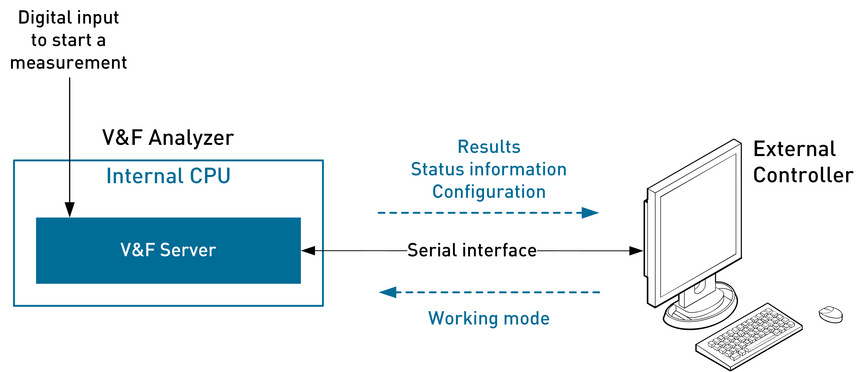

Besides the manual operation of the V&F analyzers with the V&F Client Software, V&F offers several optional interfaces, which can be used to automatically control our analyzers from any master system.

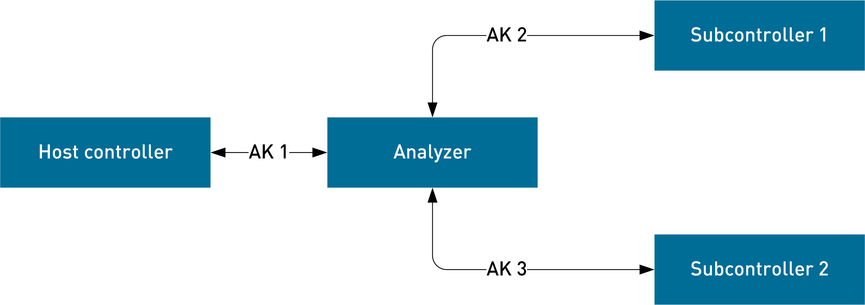

- V&F AK-Interface

- V&F Connect

- V&F EtherCAT

- V&F OPC Server

- V&F Sensor Interface