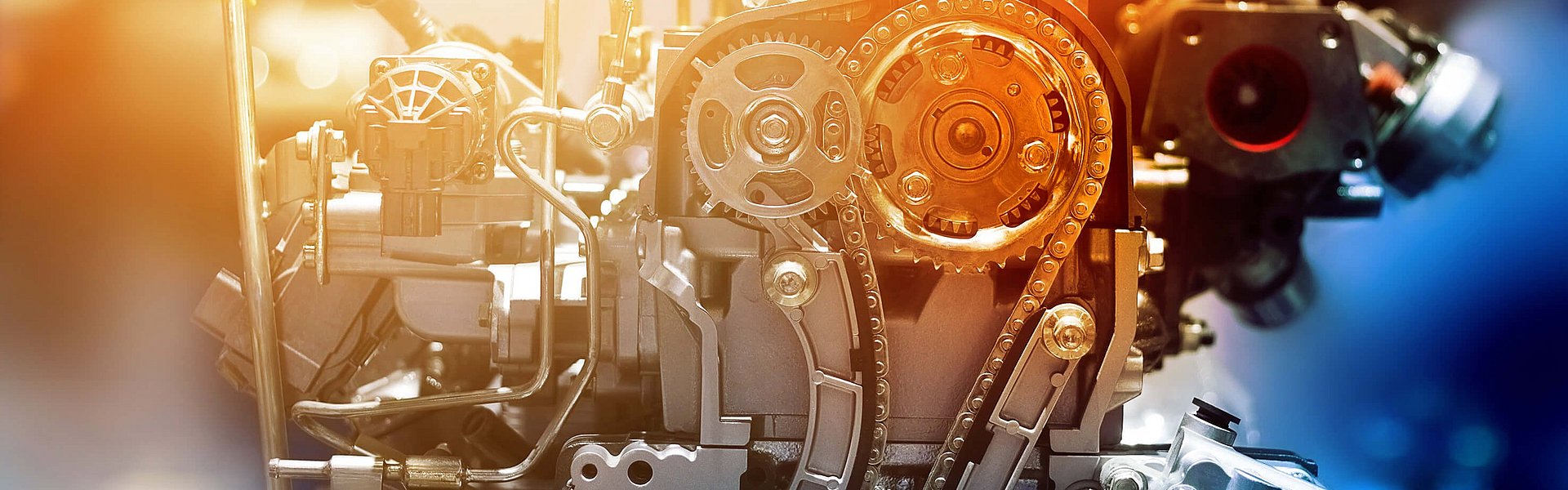

As a result of the "Renewable energy" Energy Directive 2009/28/EC, EU member states are obliged to increase the proportion of renewable energy in total energy consumption to an average of 20% by 2020. This has a direct impact on the development of internal combustion engines.

The dilution of engine oil by fuels containing ethanol, such as Super E10, or by diesel fuels containing biodiesel, can significantly alter the lubricating properties and cause damage to the engine. Since ethanol has a higher vaporization enthalpy and lower vapor pressure, fuels containing higher levels of ethanol tend to produce unfavorable mixtures during cold starting and engine warm-up compared to conventional gasoline. There is an increased likelihood of gasoline entering the oil under these engine conditions. For diesel engines, the post-injection conditions that trigger DPF (diesel particulate filter) regeneration are of particular interest. Although the chemical and physical properties of biodiesel and diesel components are similar, biodiesel fuels tend to dilute the engine oil more during DPF regeneration.

Other aspects of today's internal combustion engine development, such as the use of new combustion methods and catalyst heating, likewise facilitate oil dilution - even when using regular gasoline. Identifying strategies to counteract or optimize engine oil dilution requires a fundamental understanding of the mechanisms of fuel entry and exit into the engine oil. Measurement equipment is, therefore, necessary to determine the percentage of fuel in engine oil and preferably provide real-time results.