There is a high demand for iron and steel worldwide, and optimization of the production process is given high priority in the industry. Product quality and batch reproducibility are of utmost importance, as they represent a cost reduction in the process. A set of variables that must be measured and controlled to guarantee the best possible product are the gas compounds H2, CO, CO2, H2O involved in the production process.

Background

Solution

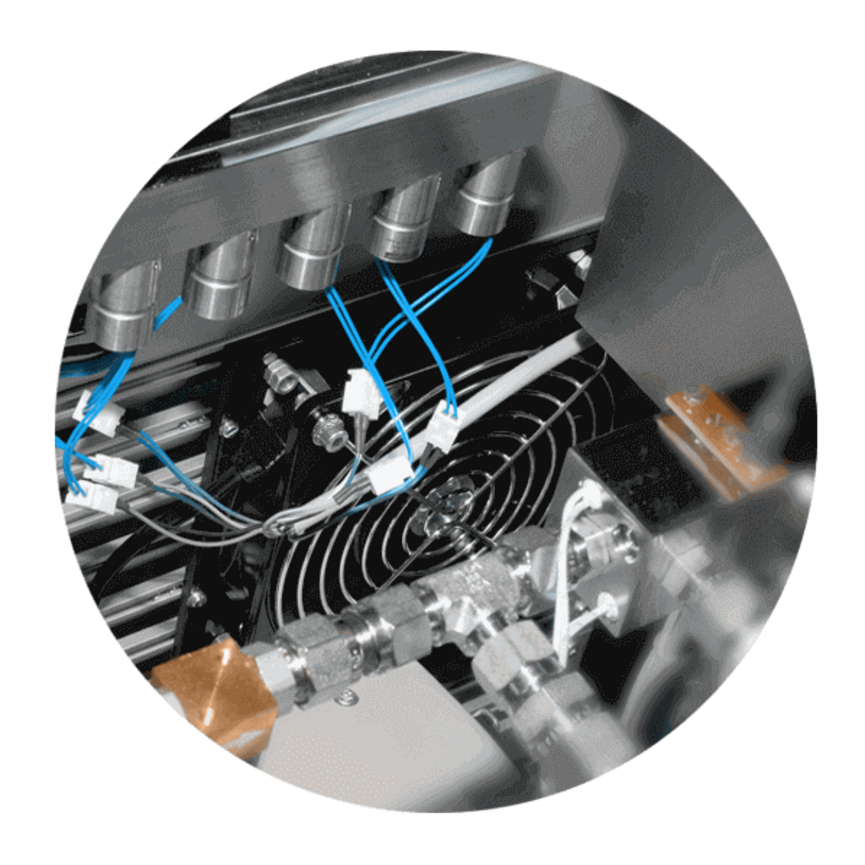

V&F offers mass spectrometer multi-component instruments to measure a range of gaseous compounds simultaneously. Within a measurement cycle of a few seconds, different concentrations can be determined with an accuracy of 5%. Typically, carbon emissions (CO, CO2 and H2) are measured in comparison to oxygen input, as well as argon and nitrogen concentrations. These parameters provide information about the efficiency of the process, diffusion characteristics and potential system leaks.

Advantages

Key features such as direct sampling, ease of implementation in existing IT/PLC environments, and rapid data acquisition make V&F instruments ideal for process control. Process parameters can be altered at any time, resulting in a more efficient workflow and hence cost reduction. Using V&F mass spectrometers during steel production is an economical way to optimize the process and the quality of the final product.

Reference clients (excerpt)