Engine oil loss is a severe problem in today’s engine development. Downsizing engines together with turbocharging, reducing piston ring thickness in combination with increased cylinder pressures result in engine oil loss. Minimizing oil loss requires knowledge of the engine conditions in which this occurs.

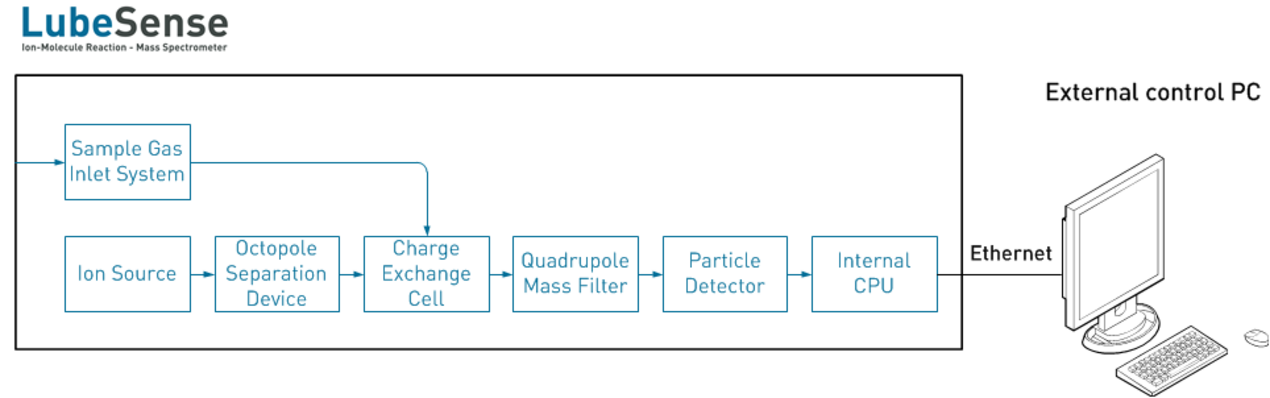

Especially for transient engine operation, a device for real-time measurements is essential to obtain time-resolved oil consumption profiles. The V&F LubeSense has been specifically designed for this task. In combination with the V&F GasOxidizer, oil consumption quantities can now be determined on-line using the SO2 tracer method.