It can occur that consumers fill PET bottles for beverages with solvents, fuels, and other substances that are harmful to health. If such contaminated PET bottles end up being recycled (PCR PET), harmful compounds can escape from the flakes. During the recycling process, the PET bottles are cleaned and shredded into flakes, after which they are available as raw material for further use. Quality control of PET flakes requires a measurement method that can quickly examine PET flake batches and immediately determine characteristic impurities so as to prevent low-quality material from entering further production steps.

Background

Solution

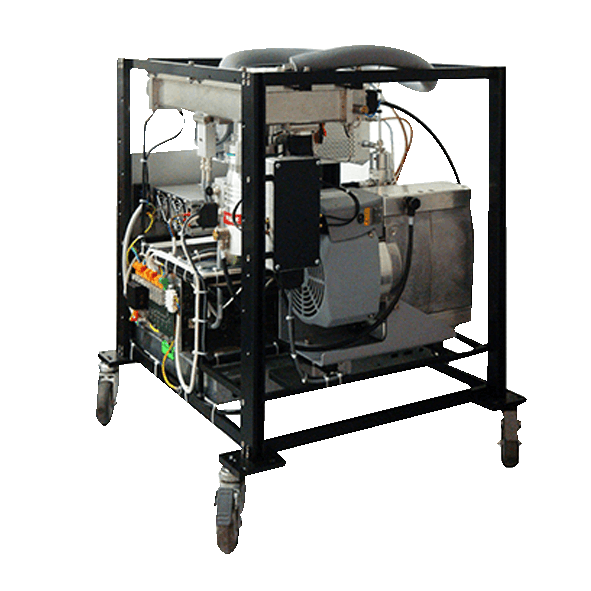

V&F's advanced IMR (Ion Molecular Reaction) technology can quickly detect typical impurities leaking from PET flakes, such as acetone, chlorobenzene, or toluene. The range of measurable compounds is wide and includes organic as well as inorganic impurities. The robust design of V&F mass spectrometers guarantees low maintenance and high reliability. The V&F mass spectrometers can be equipped with a variety of interfaces to allow good integration into automation systems such as a ProfiBus environment.

Advantage

V&F mass spectrometers provide real-time results without requiring sample preparation. Potentially hazardous gas leakage from PET flakes can be determined with high sensitivity and selectivity. IMR technology can analyze batches of PET flakes within very short time intervals, serving as a powerful tool in PET recycling quality control.

Reference clients (excerpt)