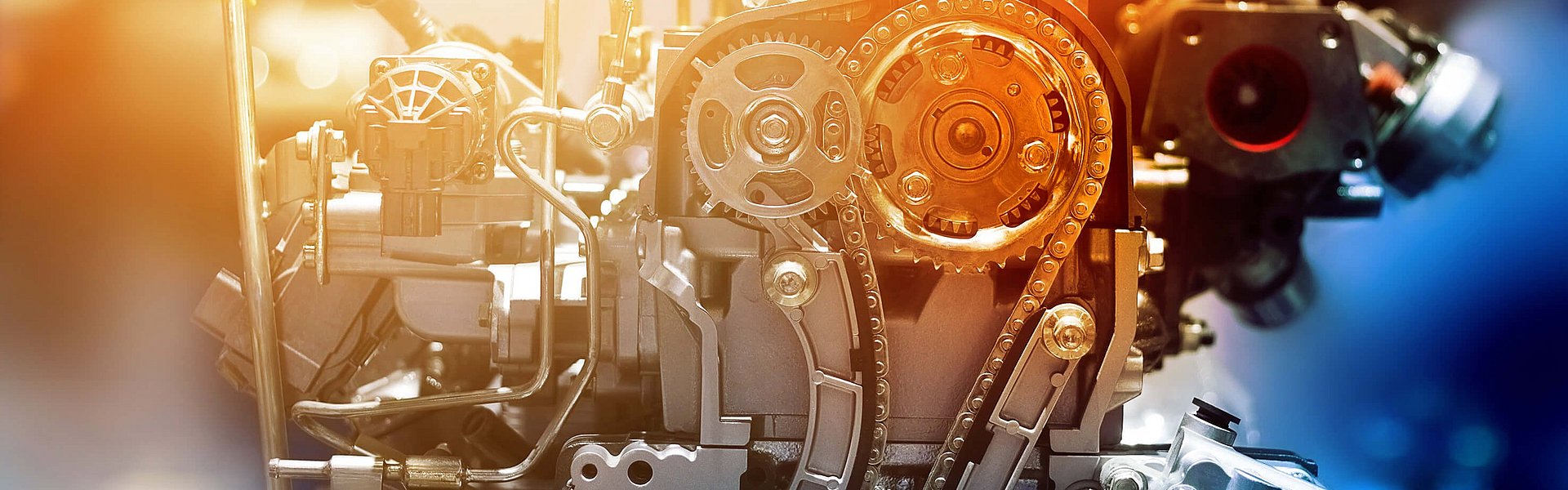

In modern engine development, the loss of engine oil represents a serious problem The downsizing of engines together with turbo charging and/or the reduction of piston ring thickness, in combination with increased cylinder pressure, leads to engine oil loss. Engine oil contains approximately 2000 - 3000 ppm of sulfur, which is oxidized during combustion, producing sulfur dioxide. This can lead to reduced catalyst activity.

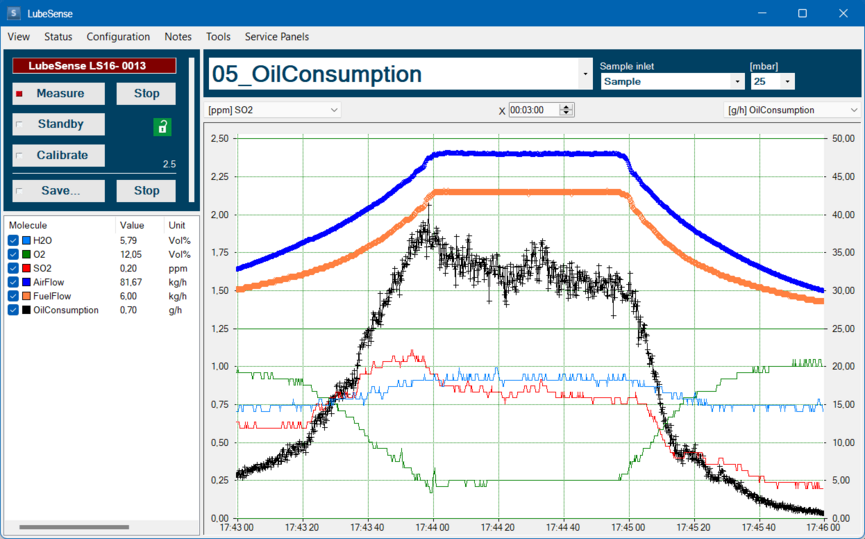

In addition, other oil by-products such as phosphorus, compromise sensor properties, leading to faulty engine operation and catalytic converter function. To be able to minimize oil loss, it is necessary to know in which engine state it occurs. Gravimetric methods can provide information on static engine operating conditions, but for dynamic engine operation, real-time measurements are necessary to obtain time-resolved oil consumption profiles.